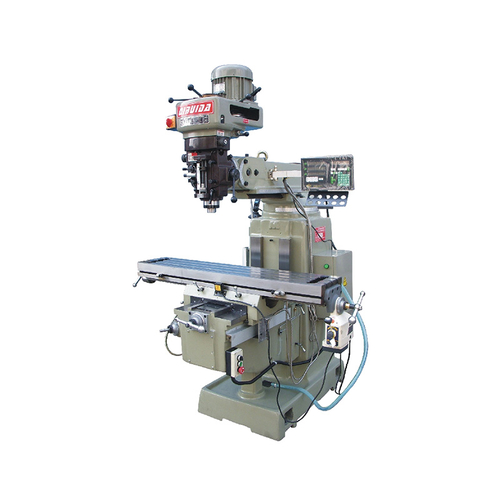

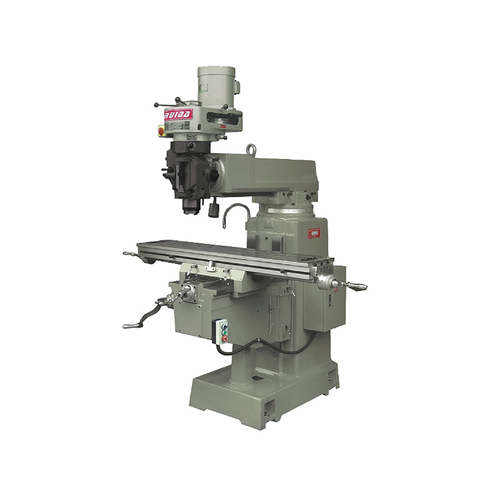

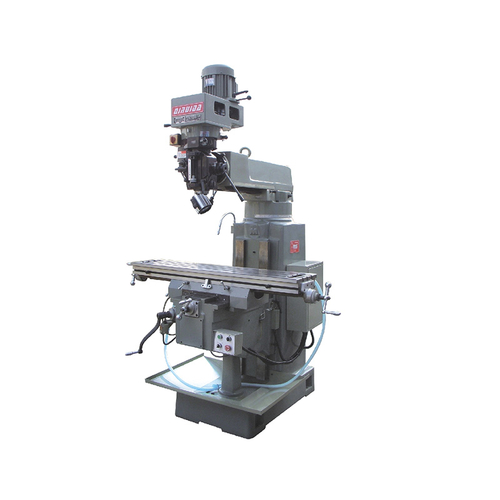

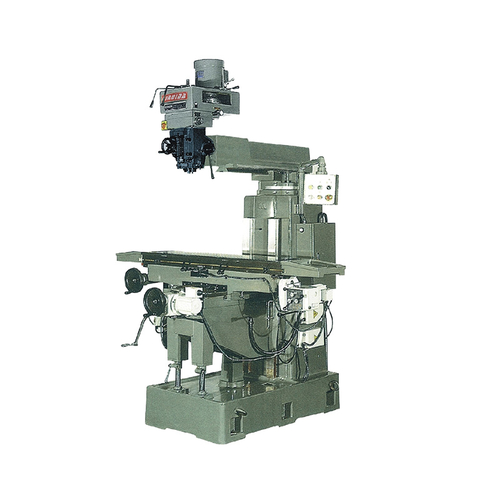

Turret Milling Machine

Machine Characteristics:

Configuration

Technical Parameters

| MODEL | QRD-2S | QRD-3S | QRD-3VS | QRD-3S/1 | QRD-4S | |

| Tible size | 230×1067 | 254×1270 | 254×1270 | 254×1270 | 254×1270 | |

| Travel | Longiude(x) | 740 | 870 | 900 | 900 | 900 |

| Cross (Y) | 320 | 380 | 380 | 380 | 380 | |

| Vertical(Z) | 360 | 360 | 360 | 360 | 360 | |

| Quill travel | 127 | 127 | 127 | 127 | 127 | |

| Spindle | Speed | 80~5440(16 speed) | 80~5440(16 speed) | 80~4200(No paragraph) | 80~5440(16 speed) | 80~5440(16 speed) |

| Taper | R8(NT30) | R8(NT30) | R8(NT30) | R8(NT30) | R8(NT30) | |

| Motor | 3HP | 3HP | 3HP | 3HP | 3HP | |

| Maximum distance from the spindle end to the working surface | 450 | 420 | 420 | 420 | 420 | |

| Machine dimension | 1520×1300×2100 | 1700×1500×2100 | 1700×1500×2100 | 1700×1500×2130 | 1700×1500×2130 | |

| Machine weight | 1000 | 1280 | 1300 | 1400 | 1500 | |

| MODEL | QRD-3SB | QRD-4SB | QRD-5SQ | QRD-5S | |

| Tible size | 254×1270 | 254×1270 | 280×1370 | 305×1370 | |

| Travel | Longiude(X) | 900 | 900 | 1000 | 880 |

| Cross (Y) | 380 | 380 | 380 | 380 | |

| Vertical{Z) | 360 | 260 | 360 | 360 | |

| Quill travel | 127 | 127 | 127 | 127 | |

| Spindle | Speed | 80~5440(16 speed) | 80~5440(116 speed) | 80~5440(16speed) | 80~5440(16speed) |

| Taper | RB(NT30) | RB(NT30) | NT40 | NT40 | |

| Motor | 4HP | 4HP | 5HP | 5HP | |

| Maximum distance from the spindle end to the working surface | 420 | 420 | 440 | 480 | |

| Machine dimension | 1700x1500×2130 | 1700x1500×2130 | 1800x1500×2210 | 1800x1500×2270 | |

| Machine weight | 1500 | 1500 | 1750 | 2000 | |

| MODEL | QRD-6S | QRD-6SH | QRD-7S | QRD-8S | |

| Tible size | 305×1370 | 330x1370 | 360x1370 | 360x1524 | |

| Travel | Longiude(X) | 880 | 1000 | 1000 | 1150 |

| Cross (Y) | 420 | 380 | 500 | 500 | |

| Vertical(Z) | 460 | 460 | 400 | 500 | |

| Quill travel | 127 | 127 | 150 | 150 | |

| Pindle | Speed | 70-3600(10 speed) | 70~3600(10 speed) | 70~3600(10 speed) | 70~3600(10 speed) |

| Taper | NT40 | NT40 | NT40 | NT40 | |

| Motor | 5HP | 5HP | 5HP | 5HP | |

| Maximum distance between the spindle end and the working surface | 620 | 560 | 660 | 660 | |

| Machine dimension | 1800×1550x 2400 | 1800x1600×2420 | 2200x1900×3000 | 2300x2000×3000 | |

| Machine weight | 2100 | 2200 | 2800 | 3000 | |

Send Us a Message

ABOUT

Ningbo GREAT Machine Tool Co., Ltd.

Our company is in the Baojia Industrial Park of Ningbo City, adjacent to the airport, highway, railway station, and bus station with very convenient transportation. We are China Turret Milling Machine manufacturers and custom Turret Milling Machine factory.Our products are suitable for producing auto accessories, textile Accessories, digital products, military products, medical instruments, mold manufacturing, aluminum casting, and so on. We import inspection equipment from Italy and Britain and conduct complete inspections for each machine, including machine tool geometry inspection, laser interference inspection, full tool test, spindle motor dynamic balance correction, etc. to ensure the high precise and stable quality of our products. In addition, we provide after-sales service. Our professional teams maintain close contact with customers and provide technical support at time if necessary. We adhere to the Diamond quality concept and keep working on it to provide products for each customer.

Professional

The sales team keeps in close contact with customers and provides technical support in time.

Quality & Cost

We have our own processing workshop. So we can provide favorable prices and high-quality products directly.

News

-

What are the innovations of Compound Machining Center compared with traditional machining machines?

With the rapid development of modern manufacturing industry, the requirements for processing efficie...

READ MORE -

How does Horizontal Machining Center's automatic tool changer work?

Horizontal Machining Center is an indispensable and efficient processing equipment in modern manufac...

READ MORE -

Unique advantages of Gantry Type Machining Center when machining large workpieces

In manufacturing, the machining of large workpieces has always been a challenging task. Traditional ...

READ MORE -

How the programming and control system of Five Axis Machining Center works

Five Axis Machining Center is an important piece of equipment in the field of modern precision manuf...

READ MORE -

How to balance the processing accuracy and speed of High Speed Drilling and Tapping Machine?

In modern manufacturing, high-speed drilling, milling and tapping machines have become important equ...

READ MORE -

How to ensure the accuracy and stability of Double Spindle Machining Center?

Double Spindle Machining Center, as an efficient CNC machine tool, is widely used in the processing ...

READ MORE

English

English 中文简体

中文简体 русский

русский

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)